Are your teams focused on delivering the work

that matters?

Companies are grappling with change across

multiple vectors: from evolving market dynamics, fierce competition, and

changing customer expectations, to new business models, shifting company

strategies and entirely new ways of working. However, where there’s turbulence,

there’s also opportunity. Innovative companies are taking advantage of these

new opportunities and finding new ways to drive continuous improvement with great execution. R Consultants, is uniquely positioned to help organizations transform the way they streamline the delivery of strategic initiatives and enable their teams to do their very best

work.

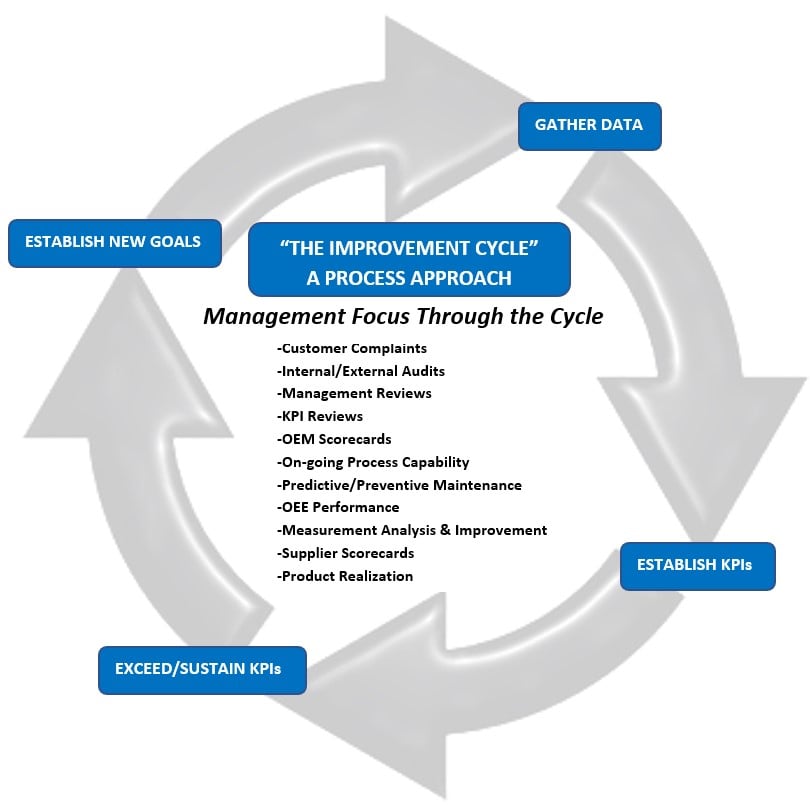

Managing Director Ken Lindahl, will work with you to validate your current KPIs(Key Process Indicators) or help establish new ones that can be monitored and leveraged for positive impacts to your bottom line. Eventually using those KPI goals as a focus for on-going continuous improvement. As seen in the above model by gathering data at key areas in the business we derive goals. Once goals are established we continue to gather data in a pursuit to exceed those goals. Once we exceed and sustain the desired level of performance we can then establish new goals and repeat the process. Continuous Improvement does not stop and is essential to be successful. It's a way of thinking, it's a culture. It's something R Consultants can assist any company willing and wanting to do better.

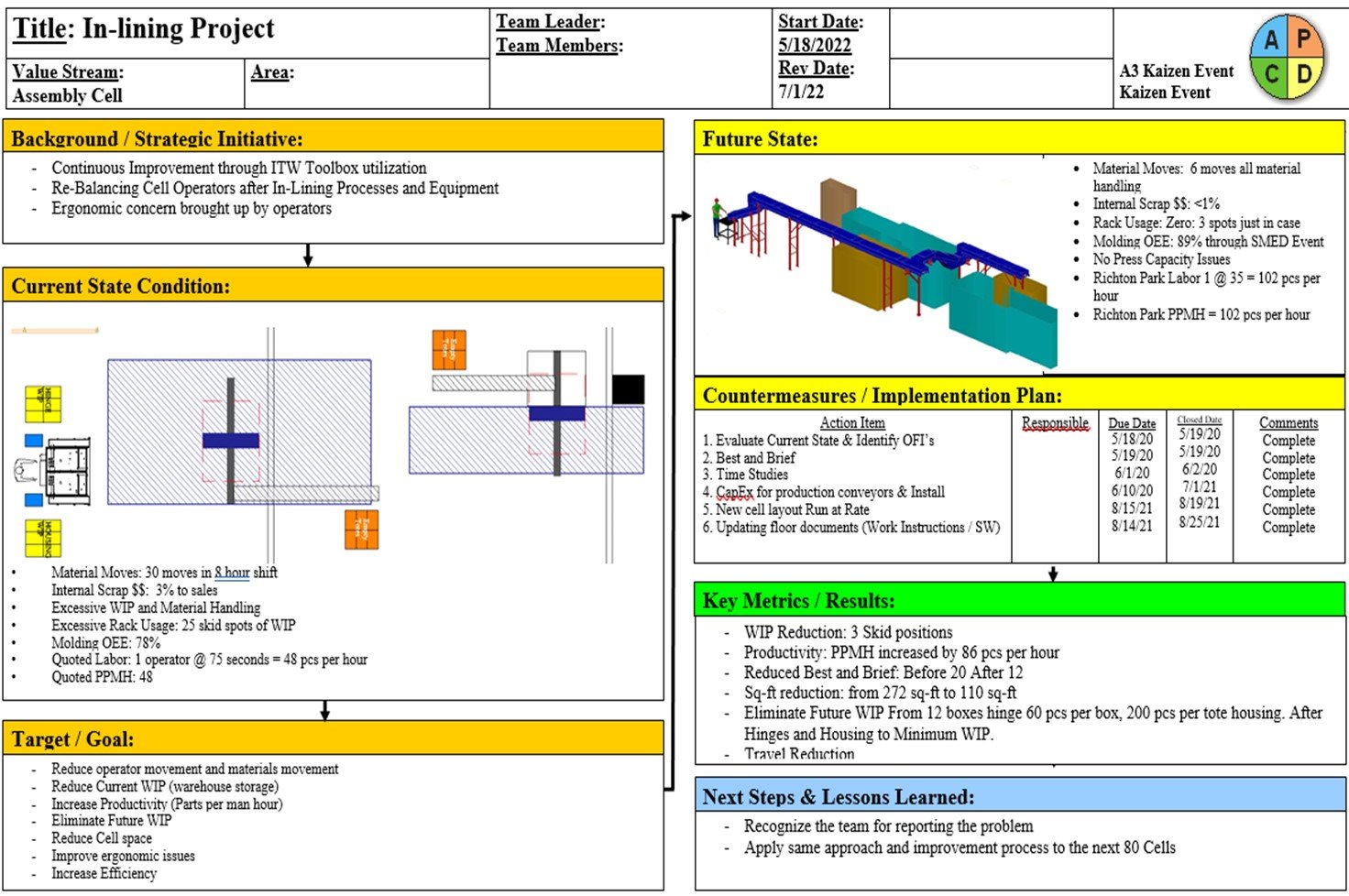

If you're looking for some smaller project help we can assist in that as well as seen below in the "Customized Work Plan".